FBE coated Ball Valve Body & Adaptor

With the policy of continual development, we have started Fusion Bonded Epoxy (FBE) coating in 1994. FBE coatings engineered for optimum corrosion protection of metal in the harshest environments, including saltwater, wastewater, petrochemicals, solvents & corrosive gases. FBE coating also provide enhanced properties for operation at elevated temperature, mechanical damage protection, compression, wear, and abrasion and cavitation resistance. FBE coating is thermosetting materials that achieve a high bond to metal surface as a result of a heat generated chemical reaction.

We have carried out FBE coating for various applications like portable water, saline water, gases etc. We have successfully executated FBE Coating on Ball Valves, Butterfly valves, Gate Valves & fittings for pipe line as per Saudi Aramco specification i.e. 09-SAMSS-091.

HOW FBE COATING PROTECTS

Fusion-bonded epoxy coating principally protects against corrosion by serving as a barrier that isolates the steel from the oxygen, moisture and chloride ions that are needed to cause corrosion. Fusion-bonded epoxy coating also has a high electrical resistance, which blocks the flow of electrons that make up the electrochemical process of corrosion. In addition to serving as a circuit breaker, the coating reduces the size and number of potential cathode sites, which will limit the rate of any corrosion reaction that could occur.

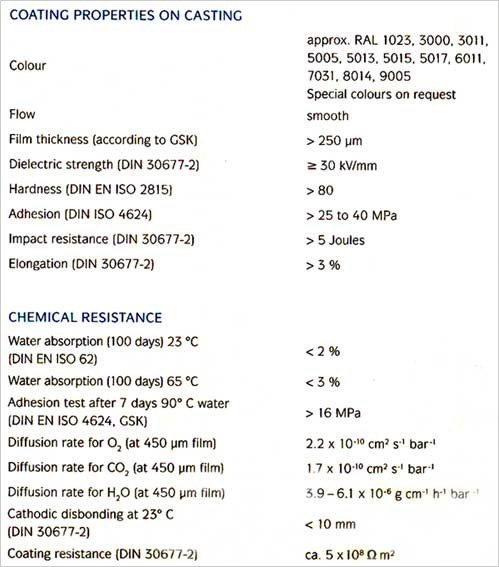

FBE Coating can be done in the range of 300 microns to 675 microns thickness. In certain cases it can be coated maximum up to 1200 microns. FBE coating is a pin hole free coating when it is coated in the range of 400 microns to 1200 microns thickness. It is been tested with maximum of 2.2 KV spark test.

Other Industrial Items

FBE coated Pipeline Parts

FBE coated Ball Valve Assembly

Fusion Bonded Epoxy (FBE) Coating

Applications :

Potable water, Sea-water, oil and gas

Items:

• Valves

• Coolers

• Pipes and fittings

• Spool